Page 4 - Barhale Catalogue Volume 1

P. 4

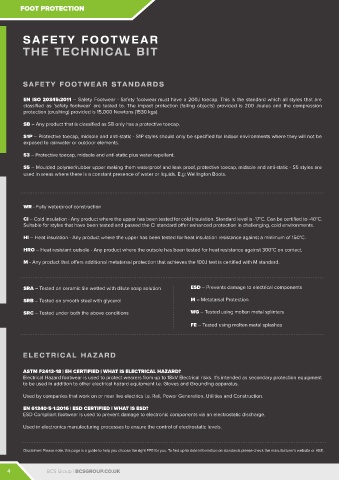

FOOT PROTECTION

SAFETY FOOTWEAR

THE TECHNICAL BIT

SAFETY FOOTWEAR STANDARDS

EN ISO 20345:2011 – Safety Footwear - Safety footwear must have a 200J toecap. This is the standard which all styles that are

classified as ‘safety footwear’ are tested to. The impact protection (falling objects) provided is 200 Joules and the compression

protection (crushing) provided is 15,000 Newtons (1530 kgs).

SB – Any product that is classified as SB only has a protective toecap.

S1P – Protective toecap, midsole and anti-static - S1P styles should only be specified for indoor environments where they will not be

exposed to rainwater or outdoor elements.

S3 – Protective toecap, midsole and anti-static plus water repellent.

S5 – Moulded polymer/rubber upper making them waterproof and leak proof, protective toecap, midsole and anti-static - S5 styles are

used in areas where there is a constant presence of water or liquids. E.g: Wellington Boots.

WR - Fully waterproof construction

CI – Cold insulation - Any product where the upper has been tested for cold insulation. Standard level is -17°C. Can be certified to -40°C.

Suitable for styles that have been tested and passed the CI standard offer enhanced protection in challenging, cold environments.

HI – Heat insulation - Any product where the upper has been tested for heat insulation resistance against a minimum of 150°C.

HRO – Heat resistant outsole - Any product where the outsole has been tested for heat resistance against 300°C on contact.

M - Any product that offers additional metatarsal protection that achieves the 100J test is certified with M standard.

SRA – Tested on ceramic tile wetted with dilute soap solution ESD – Prevents damage to electrical components

SRB – Tested on smooth steel with glycerol M – Metatarsal Protection

SRC – Tested under both the above conditions WG – Tested using molten metal splinters

FE – Tested using molten metal splashes

ELECTRICAL HAZARD

ASTM F2413-18 | EH CERTIFIED | WHAT IS ELECTRICAL HAZARD?

Electrical Hazard footwear is used to protect wearers from up to 18kV Electrical risks. It’s intended as secondary protection equipment

to be used in addition to other electrical hazard equipment i.e. Gloves and Grounding apparatus.

Used by companies that work on or near live electrics i.e. Rail, Power Generation, Utilities and Construction.

EN 61340-5-1:2016 | ESD CERTIFIED | WHAT IS ESD?

ESD Compliant footwear is used to prevent damage to electronic components via an electrostatic discharge.

Used in electronics manufacturing processes to ensure the control of electrostatic levels.

Disclaimer: Please note, this page is a guide to help you choose the right PPE for you. To find up to date information on standards please check the manufacturer’s website or HSE.

4 BCS Group | BCSGROUP.CO.UK