Page 8 - Barhale Catalogue Volume 1

P. 8

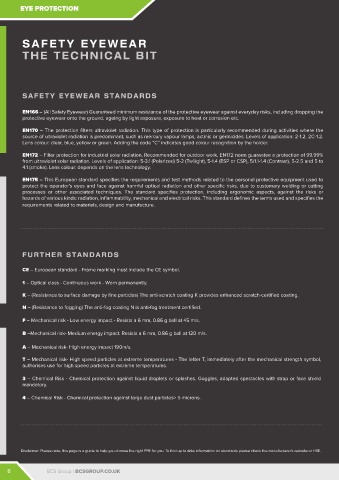

EYE PROTECTION

SAFETY EYEWEAR

THE TECHNICAL BIT

SAFETY EYEWEAR STANDARDS

EN166 – (All Safety Eyewear) Guaranteed minimum resistance of the protective eyewear against everyday risks, including dropping the

protective eyewear onto the ground, ageing by light exposure, exposure to heat or corrosion etc.

EN170 – The protection filters ultraviolet radiation. This type of protection is particularly recommended during activities where the

source of ultraviolet radiation is predominant, such as mercury vapour lamps, actinic or germicides. Levels of application: 2-1.2, 2C-1.2.

Lens colour: clear, blue, yellow or green. Adding the code “C” indicates good colour recognition by the holder.

EN172 – Filter protection for industrial solar radiation. Recommended for outdoor work, EN172 norm guarantee a protection of 99.99%

from ultraviolet solar radiation. Levels of application: 5-3.1 (Polarized) 5-2 (Twilight), 5-1.4 (ESP or CSP), 5/1.1-1.4 (Contrast), 5-2.5 and 5 to

4.1 (smoke). Lens colour: depends on the lens technology.

EN175 – This European standard specifies the requirements and test methods related to the personal protective equipment used to

protect the operator’s eyes and face against harmful optical radiation and other specific risks, due to customary welding or cutting

processes or other associated techniques. The standard specifies protection, including ergonomic aspects, against the risks or

hazards of various kinds: radiation, inflammability, mechanical and electrical risks. This standard defines the terms used and specifies the

requirements related to materials, design and manufacture.

FURTHER STANDARDS

CE – European standard - Frame marking must include the CE symbol.

1 – Optical class - Continuous work - Worn permanently.

K – (Resistance to surface damage by fine particles) The anti-scratch coating K provides enhanced scratch-certified coating.

N – (Resistance to fogging) The anti-fog coating N is anti-fog treatment certified.

F – Mechanical risk - Low energy impact - Resists a 6 mm, 0.86 g ball at 45 m/s.

B –Mechanical risk- Medium energy impact. Resists a 6 mm, 0.86 g ball at 120 m/s.

A – Mechanical risk- High energy impact 190m/s.

T – Mechanical risk- High speed particles at extreme temperatures - The letter T, immediately after the mechanical strength symbol,

authorises use for high speed particles at extreme temperatures.

3 – Chemical Risk - Chemical protection against liquid droplets or splashes. Goggles, adapted spectacles with strap or face shield

mandatory.

4 – Chemical Risk - Chemical protection against large dust particles> 5 microns.

Disclaimer: Please note, this page is a guide to help you choose the right PPE for you. To find up to date information on standards please check the manufacturer’s website or HSE.

8 BCS Group | BCSGROUP.CO.UK