Page 12 - Barhale Catalogue Volume 1

P. 12

HAND PROTECTION

HAND PROTECTION

THE TECHNICAL BIT

GLOVE COATINGS

LATEX – Supple, robust and provides excellent dry and wet grip.

NITRILE – Ideal for handling oils and fuels. Has a greater heat resistance than latex.

NITRILE FOAM – Makes control and movement more reliable. In greasy or oily environments the interaction between the glove coating

and substance improves grip, even on smooth surfaces.

POLYURETHANE (PU) – Remains supple in cold conditions. Very elastic and adapts easily to all hand movements.

HPT FOAM – Spongy, soft and durable coating that repels liquid to provide a film grip in wet or dry conditions. Has some benefits of anti-vibration.

PVC – Offers good protection from alkalis and acids. Great durability.

HAND PROTECTION STANDARDS

EN 388

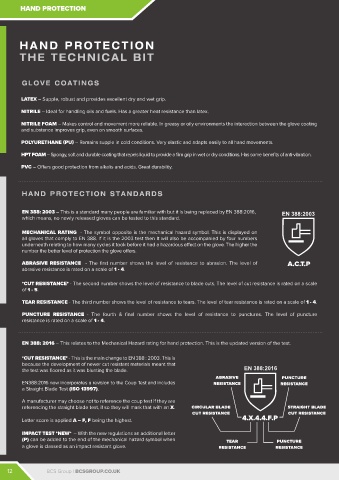

EN 388: 2003 – This is a standard many people are familiar with but it is being replaced by EN 388:2016, EN 388:2003

which means, no newly released gloves can be tested to this standard.

MECHANICAL RATING - The symbol opposite is the mechanical hazard symbol. This is displayed on

all gloves that comply to EN 388. If it is the 2003 test then it will also be accompanied by four numbers

underneath relating to how many cycles it took before it had a hazardous effect on the glove. The higher the

number the better level of protection the glove offers.

ABRASIVE RESISTANCE - The first number shows the level of resistance to abrasion. The level of A.C.T.P

abrasive resistance is rated on a scale of 1 - 4.

*CUT RESISTANCE* - The second number shows the level of resistance to blade cuts. The level of cut resistance is rated on a scale

of 1 - 5.

TEAR RESISTANCE - The third number shows the level of resistance to tears. The level of tear resistance is rated on a scale of 1 - 4.

PUNCTURE RESISTANCE - The fourth & final number shows the level of resistance to punctures. The level of puncture

resistance is rated on a scale of 1 - 4.

EN 388: 2016 – This relates to the Mechanical Hazard rating for hand protection. This is the updated version of the test.

*CUT RESISTANCE* - This is the main change to EN 388 : 2003. This is

because the development of newer cut resistant materials meant that

EN 388:2016

the test was floored as it was blunting the blade. EN 388

AbrAsive Puncture

EN388:2016 now incorporates a revision to the Coup Test and includes resistAnce resistAnce

a Straight Blade Test (ISO 13997).

A manufacturer may choose not to reference the coup test if they are

referencing the straight blade test, if so they will mark that with an X. circulAr blAde strAiGHt blAde

cut resistAnce cut resistAnce

Letter score is applied A – F, F being the highest. 4.X.4.4.F.P

IMPACT TEST *NEW* – With the new regulations an additional letter

(P) can be added to the end of the mechanical hazard symbol when teAr Puncture

a glove is classed as an impact resistant glove. resistAnce resistAnce

12 BCS Group | BCSGROUP.CO.UK